production software

print on demand solutions

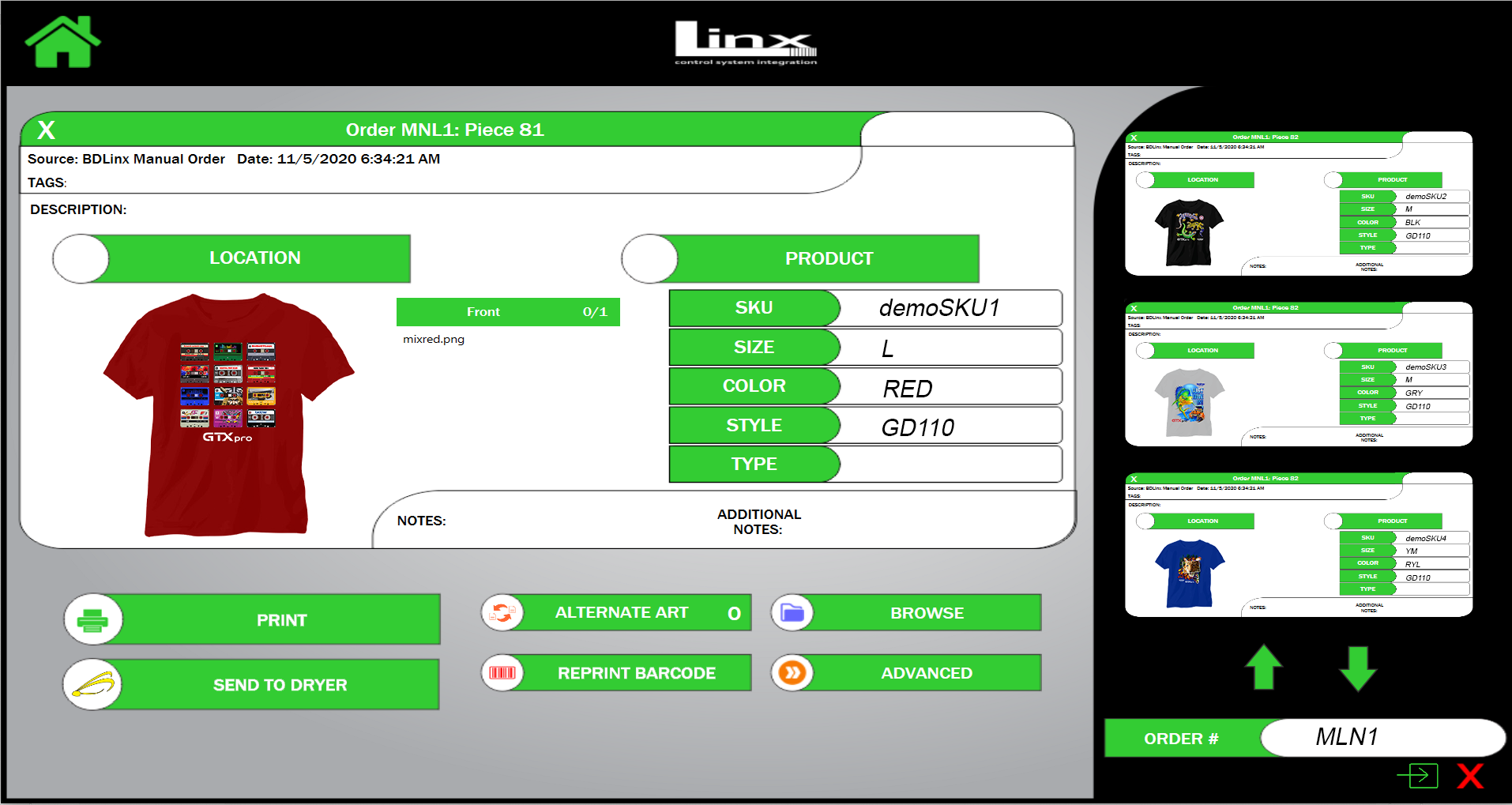

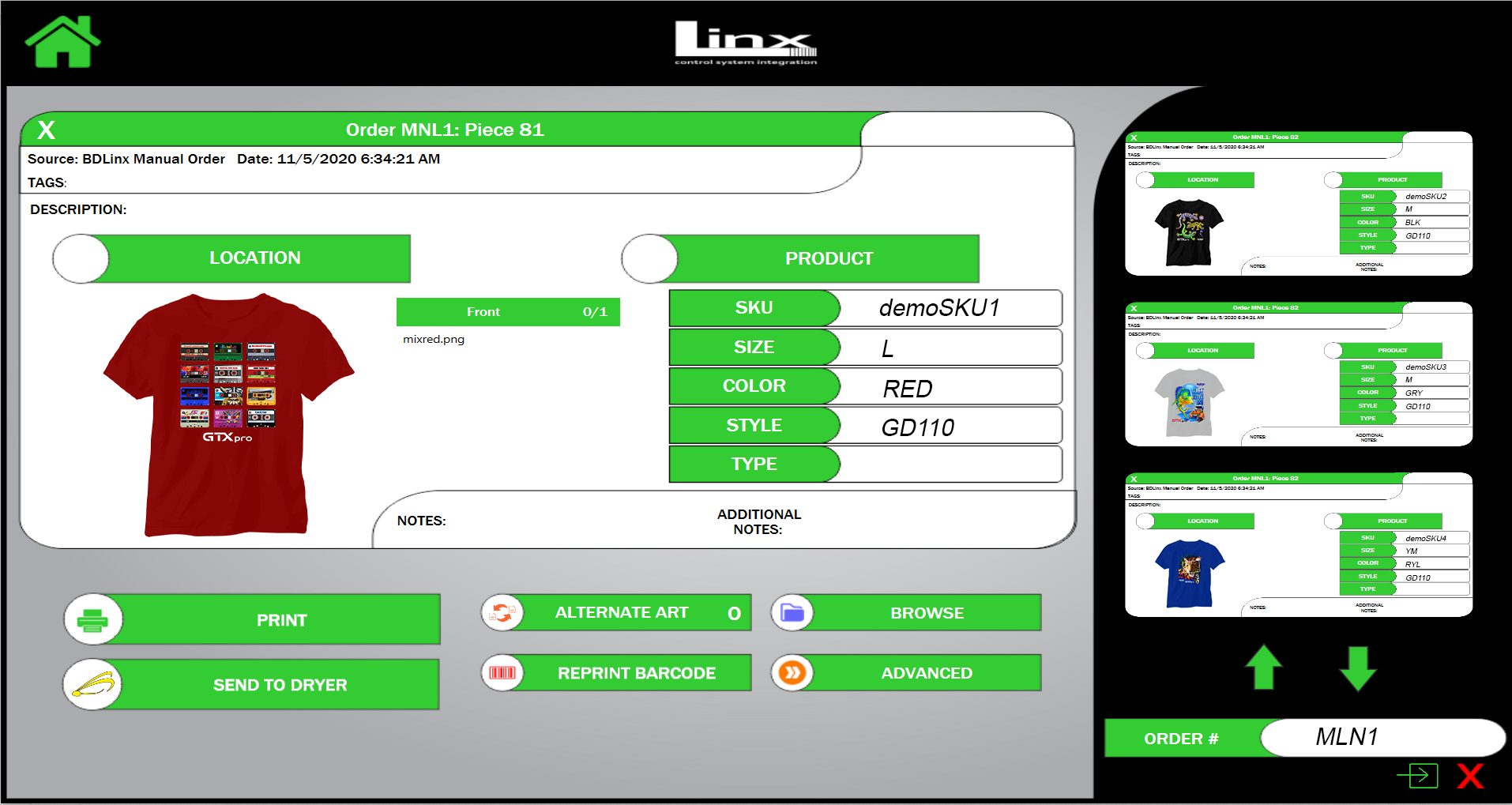

Linx features

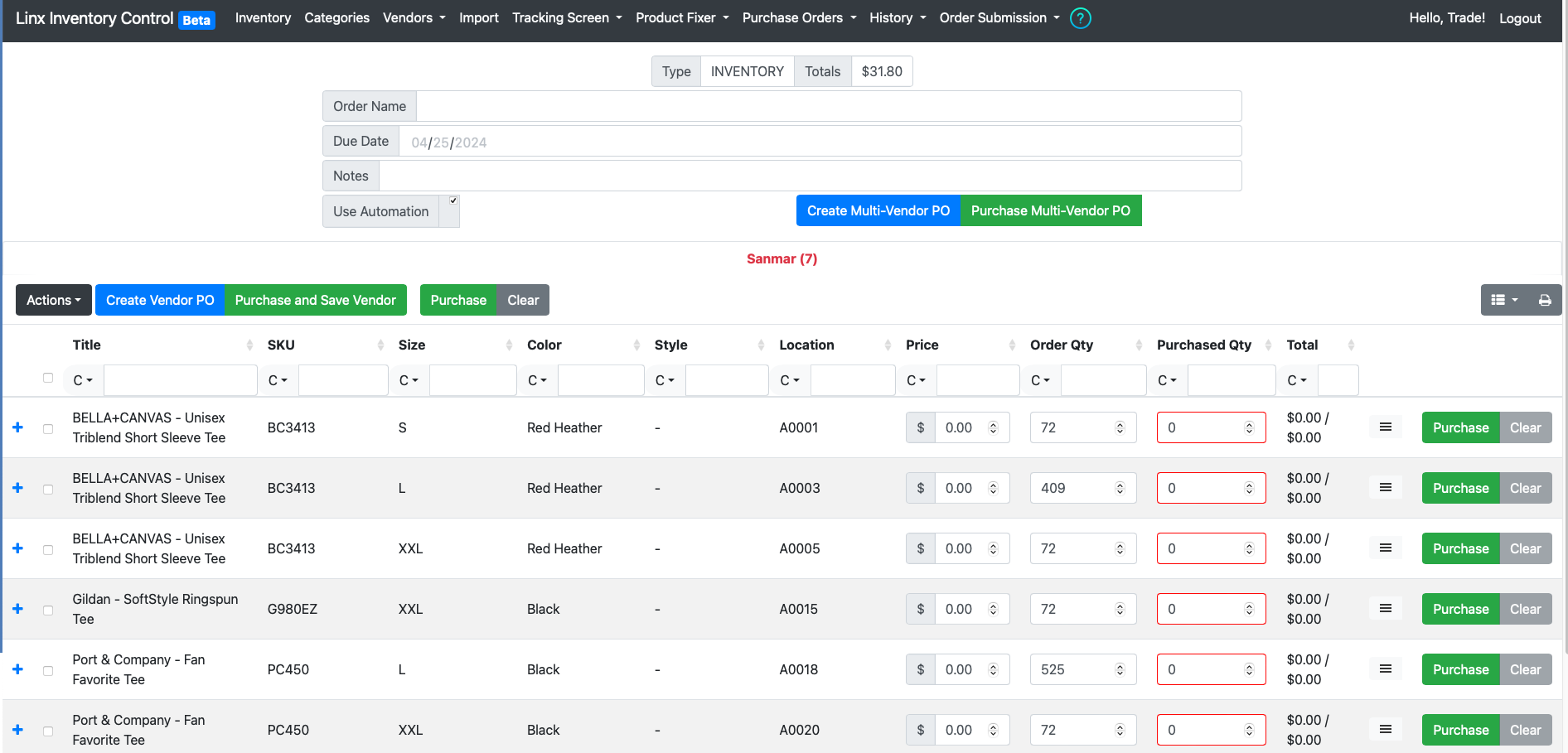

- Pull orders directly from web stores

- Push orders into ShipStation

- Automatic production of RIP files

- Automatic scaled and location envelopes

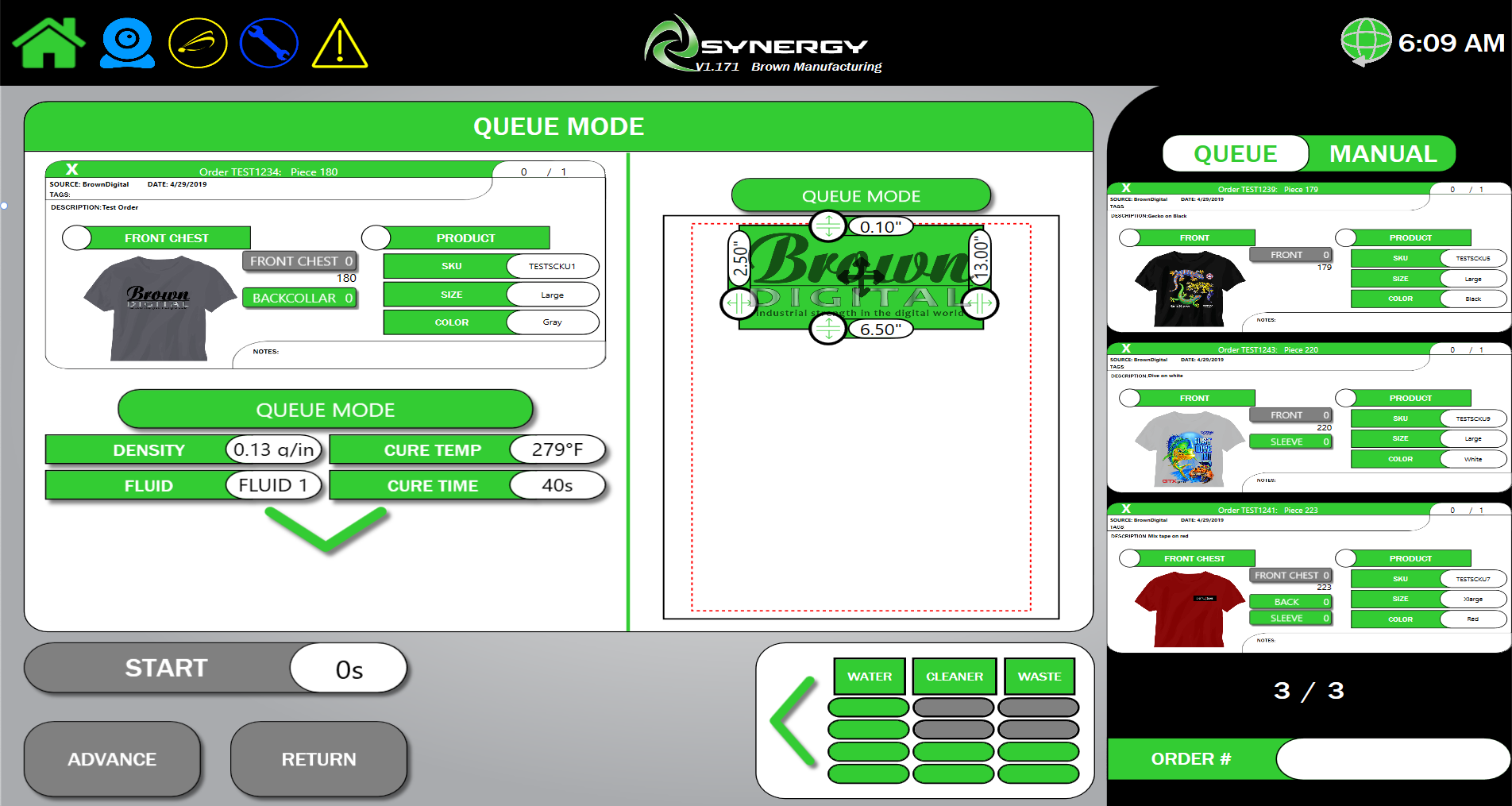

- User defined print profiles

- User defined curing profiles

- Binning system

- Connects to DTG, embroidery, engravers

- Sort orders by many factors

- Barcode driven for all processes

downloads

Beginning at a web store, information for an order is pulled into Linx and a barcode is assigned. This information includes garment data as well as art and print locations. The PNG artwork is ripped for the DTG as well as scaled for garment size and print location. The DTG operator loads the shirt, scans the code and the printer has all the information needed for production. Print specifications are preset by the user as well as pretreat and cure requirements.

Orders can be sorted by all major factors. This aids in purchasing, product picking, pretreat scheduling and customer management. At shipping, a binning system allows for gathering of multiple items of an order with notifications when an order is complete. In the QC department, if a product does not pass inspection, the barcode returns to th production schedule for a reprint.

Additional production areas can be managed by Linx. Embroidery, laser engravers, plotters and cutters as well as other options can all be barcode driven and managed withing Linx. A QuickBooks plug in will also connect your orders directly to your billing department. Custom API connections are available to give full flexibility to your production needs.